Handcrafted Wood Furnishings and Furniture

When purchasing new residential or commercial wood furniture, wood gates, wood doors, cabinets, windows, or other wood or hand carved elements, you should always question the product values, not just the pretty designs. Finding out how it's made - the raw materials it's made from - makes all the difference in determining the value regarding how long your new furnishings will last, and how much maintenance will be necessary on your part to ensure its longevity.

Educating Our Customers on Quality Craftsmanship

It is our experience when most people are shopping for wood furnishings they seldom ask the "right" questions - resulting in poor choices and loss of investment.

ArtFactory.com and artist H. J. Nick take pride in educating every one of our dealers and customers -- with full transparency and correct information and sources -- allowing the facts about how each product is made to be evaluated with no sales hype.

High Quality Wood Furnishings Are Never Made From Plywood, Laminates, Veneers, Particle Board Or Designed To Fit in a Box.

All high quality, hand made, solid wood products are never pre-made fast process glued, stapled, veneers or mystery wood and made to fit in a box for easy shipping. The best wood furnishings are made from natural air dried, solid furniture quality wood handmade by a master craftsman using age old tried and tested mortis and tenon joints, pegged and doweled methods, using several process hand finishes that are in the wood - not just sprayed on. Hand crafted wood furniture and furnishings are built to last forever, always getting better and gaining value with time, and require little to no maintenance like any fine, investment quality, collectible antique.

Table of Contents

- - H. J. Nick - Artist Designer

- - Investment Quality Is Important

- - Guarantee & Satisfaction Warranty

- - How it's Made

- - Fine Furnishings Begin with Natural Materials

- * How It's Made - Wood Products

- - Master Hand Carving Information

- - How Its Made "Iron" - Master Blacksmithing

- - Facts About Leather Furniture

- - Stone, Marble & Granite

- - Art Factory Fine Art Finish Procedures

- - Finishes To World Class Antiquity Standards

- - American Vintage Restoration

- - More Door Details / Installation Info

- - Original Art or Limited Edition

- - Become an Interior Designer

- - A True Story About Mary

- - Dealer Design Policies & Rules

- - Web Site Terms And Conditions

- - Policies and Terms - A Must Read

Most fast process companies keep you focused on the design, color, and cheaper price - not the merits of how it's made - because the facts disclosed on these fast-process particle board and veneer spray finished products will not get your business. Most "slick operators" of these fast production companies try to compare their "design" to our high quality - solid handmade in America, solid wood, real stone, epidermis hide American-tanned fine leathers or real hand-forged by master blacksmiths - custom products in hope of dazzling you with the similarity of their fast-process, fake, designed to fit in the box, low quality, cheap furniture or composite doors. Keep in mind, if you're not comparing apples to "same" apples, you're not getting a bargain - you're being fooled.

Beware of False Advertisement

Examples of verbiage used by big-name "fake" furniture sellers (or "Slick Operators") - taken word-for-word from their advertisements:

"Blank Company" presents the Fancy name II Collection which features classic Corinthian fluted columns (which means fake paste board, hollow, non-structural columns) and subtle application of shell-like carvings (which means fake fast process cnc, resin, or molded copies of real carvings) that reminisce the style of old world Southern Europe.

A harmonious working of metal (which means hollow cold-bent painted, mystery thin walled metal) marble like (meaning real slivers, veneers or fake simulated marble, mostly glued to paste board), leather (usually re-polished suede foreign leathers processed with alkalis, pigeon poo, formaldehyde or embalming fluids), and wood (some veneered mystery wood or partial boards made from sawdust and glue) are featured throughout virtually every piece (means every inch of this product is the same foreign junk, no matter the brand name made to fit in the shipping box).

Fancy name II draws its inspiration from its namesake city that sits on the majestic and romantic Mediterranean Sea; drawing individuals from all over the world to appreciate its consistent climate and historical architecture. The family of furniture comes finished in elegant Silver Pearl (which is a lot of flowery nonsense to explain a cheap, fast sprayed on fake finish) to allow Fancy Name to fit into any decor (here they are using diversion tactics to get you away from asking the real questions, such as what's the warranty, how it's really made, what it's made from, where was it made, or who made it).

We believe THEIR theory is "Why Build Quality When You Can Just Fake It"

Many of these companies make 1000% markups or more - with no warranty or conscience, who will know? - and if you read their warranty they have no legal responsibility (and they are counting on you to not read their fine print). We are not saying all big name brands offer poor quality products, such as cars, computers, etc. We are saying almost all big name brand furniture, doors, gates, lighting, and hardware - made in the last 15 years - are foreign-made with little or no quality, fit this description bar none, and are costing you your hard earned investment monies and many Americans their jobs.

Due to These Huge Markups - Many Times, Our Prices are LESS for a Similarly Designed Product that We Custom Build for You

Contact Us & Correct Us

We challenge any of these big brand name furniture companies - we all used to be able to trust - to dispute our claims. If you can prove us wrong, we will publish it for all to see. Contact us or call 1-800-292-0008.

Our Sole Purpose of Educating You With the Genuine Facts on How It's Made is that we believe our customers are smart. If educated with the solid, proven, indisputable information necessary to know the difference between the fake and faux, they will - armed with these facts - choose ArtFactory.com to be their custom furnishings manufacturer. We also believe that our customer, once they have received their product from us, will refer us to their friends, family, and colleagues due to our developed trusted relationship. Thus, making this age old quote true again:

Contributors of the following information on this page, derived from hundreds of years of collective knowledge, include volunteer work from architectural university students and many experts from around the world who are interested in advancing the lost art of quality, hand made by master craftsman, American furnishings, along with our non-profit foundation for the advancement of these fine arts for future generations.

How It's Built - Understanding True Quality Wood Furnishings

Joinery, material and craftsmanship determine quality and future maintenance requirements. All high quality doors and furniture are natural, air cured, solid wood, full length timber and never laminated or fast process kiln dried.

Joinery, material and craftsmanship determine quality and future maintenance requirements. All high quality doors and furniture are natural, air cured, solid wood, full length timber and never laminated or fast process kiln dried.

Although many doors and wood furnishings appear to be high quality, you should never be fooled by pretty photos and flowery statements. All quality products stand on their own merits.

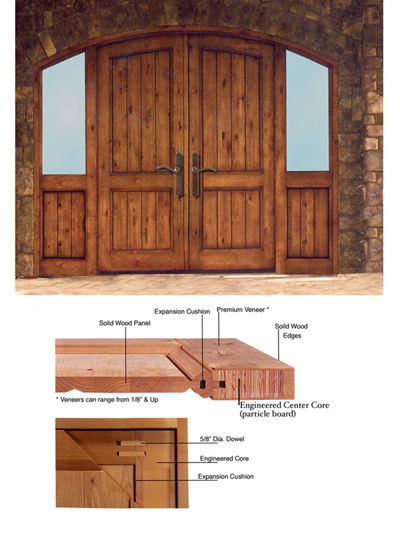

These Pretty Photos Below are Not Solid Wood Doors

These are limited warranty, veneered, high maintenance, particle board, and engineered core doors being passed off by many American and foreign furniture and door manufacturers as high quality solid wood doors.

Warning: Warp-Resistant Engineered Core usually translates into; "How can we use paste board and veneered materials and make them sound better than the tried and tested mortise and tenon, hand crafted, solid wood doors?"

This is an example of mass production companies trying to turn a negative into a positive sales tool. Many manufacturers have veneered the wood surface, and cored the center of their premium long lengths of lumber, just to keep the cost of materials down and their profits up. Always keep in mind if the wood product you're buying from another manufacturer is made from a veneer - or "engineered" wood - it usually means that they are using low quality materials, but trying to make it look and sound better. This result is often reflected in their limited warranty. Educate yourself, because there is no quality substitution for hand hewn, pegged and dowelled, solid, full length timber furniture construction - we build furnishings to last generation after generation.

This is an example of mass production companies trying to turn a negative into a positive sales tool. Many manufacturers have veneered the wood surface, and cored the center of their premium long lengths of lumber, just to keep the cost of materials down and their profits up. Always keep in mind if the wood product you're buying from another manufacturer is made from a veneer - or "engineered" wood - it usually means that they are using low quality materials, but trying to make it look and sound better. This result is often reflected in their limited warranty. Educate yourself, because there is no quality substitution for hand hewn, pegged and dowelled, solid, full length timber furniture construction - we build furnishings to last generation after generation.

- This laminated method of door or furniture building will never stand the test of time

- Laminated always means "Until the Glue Gives Up"

- We Never Veneer or Laminate - only full length, solid, domestic timber, air dried is used

Quality Built Custom Furniture

At ArtFactory.com we offer only American made, Original Craft - not reproduction - made in the same hand and materials as the original, dictated by the historical design records. All our custom handcrafted wood furnishings are hand hewn, joined mortise and tenon joints with proven tried and tested, fine art, master crafting methods. We pride ourselves on building the old fashioned way "when everything made in America was built to last forever" and furniture craftsmen were proud to sign their work.

All species of wood are available for our designer custom wood furnishings. Structural frames are crafted using full length, solid timber, mortise and tenon joints - no fake laminates, no scarf joints, no glued up parts, no veneers, no bolt-on legs. Our high quality furniture master craftsmanship insures your furnishing will become a true family heirloom and valuable antiquity - standing the test of time, backed by our forever guarantee.

All species of wood are available for our designer custom wood furnishings. Structural frames are crafted using full length, solid timber, mortise and tenon joints - no fake laminates, no scarf joints, no glued up parts, no veneers, no bolt-on legs. Our high quality furniture master craftsmanship insures your furnishing will become a true family heirloom and valuable antiquity - standing the test of time, backed by our forever guarantee.

Any carvings on your wood door, gates, or furniture is hand carved by our master carvers - not CNC machined or faux casted resin carving. On our furnishing finishes we don't use fast spray-on or fake paint jobs, but utilize a 10 process, hand rubbed fine art finish that is on par with world class antique collector standards.

"Through the sharing of knowledge and experience, we advance the arts and enrich mankind's high cultural environment."

H.J. Nick

Fine Art Quality Craftsmanship

-

Through Fine Arts and Master Craftsmanship All Our Lives are Elevated to a Higher Level

-

Many of History's Finest Designs Have been Copied by Modern Fast on the Cheap Production Manufacturers

-

Navigating Through the Fake and Faux Can Be a Daunting Task in Today's Marketplace

-

Natural Materials and American Master Craftsmanship Cannot Be Replaced with Modern Fast Process Methods

Let's Examine Imported Mahogany Doors and Furniture

Honduran Mahogany is not the same as the genuine furniture quality, domestic mahogany of the past. Honduran mahogany is not really mahogany. This mystery wood, or rain forest woods, and other renamed woods are not what they are represented to be. The materials your product is made from, and how it's truly constructed, make the difference between requiring little or no maintenance to maintain and your furnishing standing the test of time. (Remember: Pretty photos do not make a good product.) At ArtFactory.com we never use foreign "mystery" woods, because the finished product is never up to our high quality, custom furnishing standards.

Honduran Mahogany is not the same as the genuine furniture quality, domestic mahogany of the past. Honduran mahogany is not really mahogany. This mystery wood, or rain forest woods, and other renamed woods are not what they are represented to be. The materials your product is made from, and how it's truly constructed, make the difference between requiring little or no maintenance to maintain and your furnishing standing the test of time. (Remember: Pretty photos do not make a good product.) At ArtFactory.com we never use foreign "mystery" woods, because the finished product is never up to our high quality, custom furnishing standards.

Beware of "Solid" Doors Made from Scarf Joined Scrap Wood

The doors shown below are scarf joined, solid Honduran mahogany doors - meaning they are made of short lengths of scrap (so called Mahogany) wood. For example, many companies make this statement: "Honduran or Brazilian Mahogany wood is used to manufacture our premier selection of Solid Entry Doors or Furniture". Technically these other resellers are not telling a lie, they are simply omitting some important negative facts. Their doors are made up of scarf joints, splice joints, and glue, to create a longer piece of lumber out of their scrap materials. The joints are then sand filled and finished to hide their joints misleading you into believing this was one solid wood piece. Sometimes, shorter sections of wood inside the door are used to make a frame, and then particle board and a thin mahogany veneered surface is added by a laminating machine. Their manufacture methods results a high maintenance, low quality way to make a cheap product seem valuable to their customers.

The plain scarf is not preferred when strength is required, so it is often used in decorative situations, such as the application of trim or moulding. The use of modern high-strength adhesives can greatly increase the structural performance of a plain scarf joint. However, when used in exterior products, such as doors, this method is never used by top quality door builders. The scarf joint is a method of using scrap pieces of wood to make long lumber. Many manufacturers use scarf joints and splice joints in order to use exotic scrap materials, or when longer premium lumber is not available or material scraps are being used. For example: This low quality door, shown below, was created by another company by gluing together scrap pieces of mahogany using a method known as scarf joinery, combined with CNC machine carving, and a hollow tube, cold bent, metal faux-painted grill.

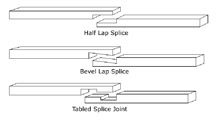

Scarf Joint in Woodworking

Scarf Joint in Woodworking

There are two distinctly different categories of scarf joints, based on whether the joint has interlocking faces or not. A plain scarf joint is simply two flat planes meeting on an angle, relative to the axis of the stock being joined, and depends entirely on adhesive and/or mechanical fastening (screws, bolts, etc.) for all its strength. Structured scarf joints include hooked, keyed, and nibbed scarf joints and are some examples of interlocking scarf joints which offer varying degrees of tensile and compressive strength, though most still depend on mechanical fastening to keep the joint closed.

Splice Joint in Woodworking

A splice joint is a method of joining two members, end to end in woodworking. The splice joint is used when the material being joined is not available in the length required. It is an alternative to other joints, such as the butt joint and the scarf joint. Splice joints are stronger than unreinforced butt joints, and have the potential to be stronger than a scarf joint. They are more visible than a scarf joint but may be preferred when more strength is required. Splice joints are therefore most often used when structural elements are required in longer lengths than the available material. The most common form of the splice joint is the half lap splice, which is common in building construction, where it is used to join shorter lengths of timber into longer beams. The splice joint should never be used in quality wood furnishings or door building. Many unscrupulous manufacturers offer furniture and doors made by this method, and the result is never positive.

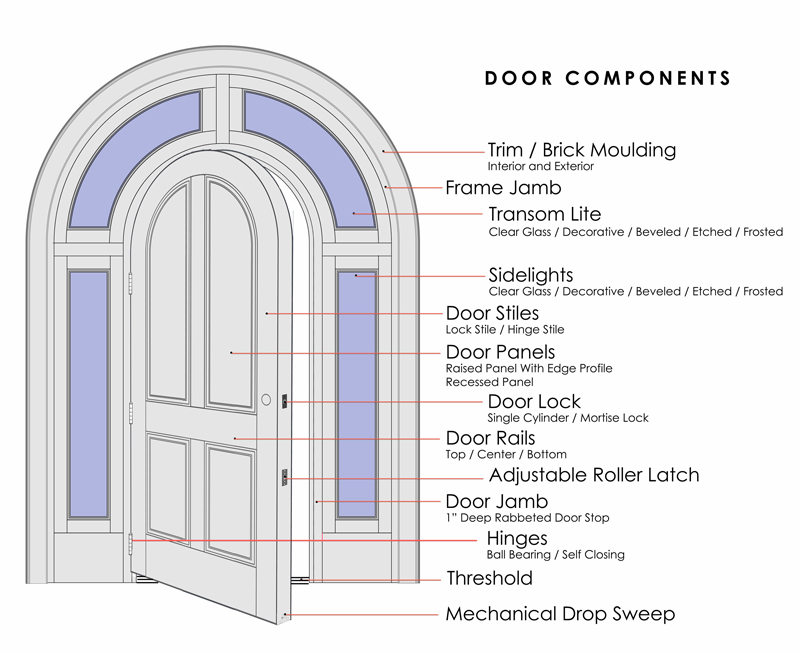

Understanding Door Terminology

Door terminology is presented in simple terms that anyone can understand. These diagrams are aids so that you may educate yourself and your client on door terminology. Many furniture and cabinet terms are also similar.

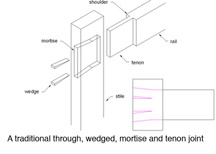

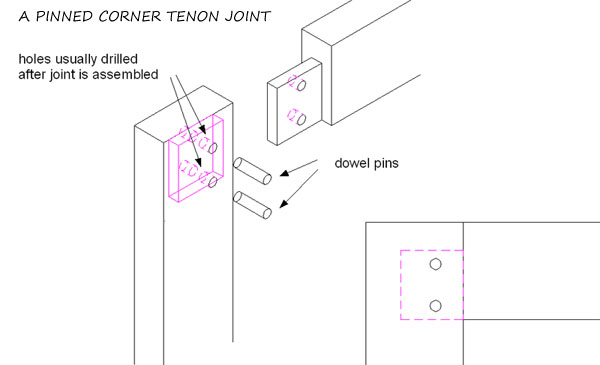

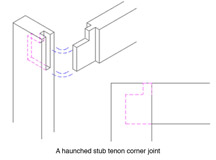

History of Joinery and Terminology

Mortise and Tenon Joints, Simple and Strong. The mortise and tenon joint has been used for thousands of years by woodworkers around the world to join pieces of wood, usually when the pieces are at an angle close to 90°. Although there are many variations on the theme, the basic idea is that the end of one of the members is inserted into a hole cut in the other member. The end of the first member is called the tenon, and it is usually narrowed with respect to the rest of the piece. The hole in the second member is called the mortise. The joint may be glued, pinned, or wedged to lock it in place. This joint is also used with other materials and, for example, is a traditional method for Stonemasons and Blacksmiths.

Mortise

A mortise is a cavity cut into a timber to receive a tenon. There are several kinds of mortises.

- Open mortise - A mortise that has only three sides. (See Bridle joint).

- Stub mortise or "suicide" joint - A shallow mortise, depth depends on the size of the timber; also a mortise that does not go through the work-piece (as opposed to a "through mortise"). The back is wider, or taller, than the front, or opening. The space for the wedge initially allows room for the tenon to be inserted, the presence of the wedge, after the tenon has been engaged, prevents its withdrawal. Sometimes called a "suicide" joint - since it is strictly a "one way trip".

- Through wedged half-dovetail - A wedged half-dovetail mortise that passes entirely through the piece.

Tenon

A tenon is a projection on the end of a timber for insertion into a mortise. Usually the tenon is taller than it is wide. There are several kinds of tenons.

- Stub tenon - A short tenon; depth depends on the size of the timber; also a tenon that is shorter than the width of the mortised piece so the tenon does not show (as opposed to a "through tenon").

- Tusk tenon - A kind of mortise and tenon joint that uses a wedge-shaped key to hold the joint together.

- Through tenon - A tenon that passes entirely through the piece of wood it is inserted into, being clearly visible on the back side.

- Teasel tenon - A term used for the tenon on top of a jowled or gunstock post, which is typically received by the mortise in the underside of a tie beam. A common element of the English tying joint.

- Top tenon - The tenon that occurs on top of a post.

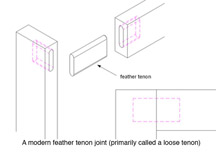

- Feather tenon - A round-shouldered machined fillet or feather which is glued into a machine (router) made slot or mortise on each side of the joint.

Mortise and Tenon Joints Info

Mortise and Tenon Joints Strength - Generally the size of the mortise and tenon is related to the thickness of the timbers. It is considered good practice to proportion the tenon as one-third the thickness of the rail, or as close to this as is practical. The haunch, the cut away part of a sash corner joint that prevents the tenon coming loose, is one-third the length of the tenon and one-sixth of the width of the tenon in its depth. The remaining two-thirds of the rail, the tenon shoulders, help to counteract lateral forces that might tweak the tenon from the mortise, contributing to its strength. These also serve to hide imperfections in the opening of the mortise.

Mortise and Tenon Joints History - Mortise and tenon joints date back to ancient history. Mortise and tenon joints have been found joining the wooden planks of the "Khufu ship", a 43.6m long vessel sealed into a pit in the Giza pyramid complex of the Fourth Dynasty around 2,500 BC. They have also been found in archaeological sites in the Middle East, Europe and Asia. The 30 sarsen stones of Stonehenge were dressed and fashioned with mortise and tenon joints before they were erected between 2600 and 2400 B.C.

Finger Joint Info

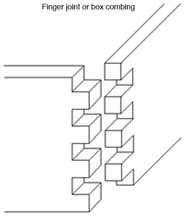

Finger Joint - Box Joint - Comb Joint

The finger joint - (also known as "box joint" or "comb joint") is made by cutting a set of complementary rectangular cuts in two pieces of wood, which are then glued. To visualize a finger joint, simply interlock the fingers of your hands at a ninety degree angle; hence the name "finger joint." It is stronger than a butt or lap joint, and often forms part of the overall look of the piece.

Finger Joint History - The history of the finger joint is believed to have begun with wooden produce boxes or crates in the days before modern, man-made materials. Finger joints were originally cut by hand with saws and sharp chisels.

In modern times they are easily and quickly made with a table saw or router and a jig or fixture, which can be shop-made or purchased from a speciality woodworking supply store. A finger joint jig typically consists of a moving fence with an indexing pin that is used to evenly space out the cuts. The fence is moved over a cutting blade making a cut that is then moved over the indexing pin so the next cut can be made.

Finger Joint Strength - The strength of a finger joint comes from the long-grain to long-grain contact between the fingers, which provides a solid gluing surface. The number of contact points also allows for more gluing surface as opposed to a butt joint or a rabbet joint.

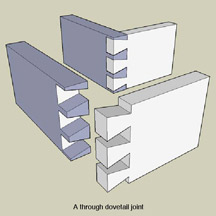

Dovetail Joint Info

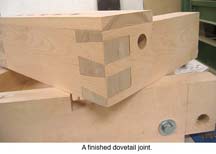

Dovetail Joint  A dovetail joint or simply dovetail is a joint technique most commonly used in woodworking joinery. Noted for its resistance to being pulled apart (tensile strength), the dovetail joint is commonly used to join, for example, the sides of a drawer to the front. A series of pins, cut to extend from the end of one board, interlock with a series of tails, cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners.

A dovetail joint or simply dovetail is a joint technique most commonly used in woodworking joinery. Noted for its resistance to being pulled apart (tensile strength), the dovetail joint is commonly used to join, for example, the sides of a drawer to the front. A series of pins, cut to extend from the end of one board, interlock with a series of tails, cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners.

Dovetail Joint History - The dovetail joint pre-dates written history. Some of the earliest known examples of the dovetail joint are in furniture entombed with mummies dating from First Dynasty of ancient Egypt, as well the tombs of Chinese emperors. The dovetail design is an important method of distinguishing various periods of furniture. Some of these ancient joints and has been found joining the wooden planks of the "Khufu ship", a 43.6m long vessel sealed into a pit in the Giza pyramid complex of the Fourth Dynasty around 2,500 BC. It has also been found in archeological sites in the Middle East, Europe and Asia. In traditional Chinese architecture, wood components such as beams, brackets, roof frames and struts were made to interlock with perfect fit, without using fasteners or glues, enabling the wood to expand and contract according to humidity. Archaeological evidence from Chinese sites show that by the end of the Neolithic period, mortise and tenon joinery was employed in Chinese construction. The 30 sarsen stones of Stonehenge were dressed and fashioned with mortise and tenon joints before they were erected between 2600 and 2400 B.C.

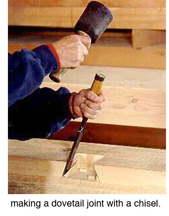

It Takes a Master Craftsman to Hand Cut Perfect Joints

The angle of slope varies according to the wood used. Typically the slope is 1:6 for softwood and a shallower 1:8 slope for hardwood. Often a slope of 1:7 is used as a compromise - perhaps using a dovetail template for marking out.

When being cut by hand, there are two schools of thought as to whether the pins or the tails should be cut first. For pins first, the pins are laid out and cut by the chosen method, then the outline of the pins is transferred to the face of the tail board. For tails first, the tails are laid out and cut and then the outline is transferred to the end grain of the pin board. Each has advantages and it is a personal choice as to which is chosen.

Hand cut dovetails can often be distinguished from machine-cut dovetails by the width of the pins. It is possible to have pins that are almost triangular when cut by hand that are not possible when cut with a router, owing to the thickness of the router bit's shank. These narrow pins are known as London Pins.

Types of Dovetail Joints

A through dovetail joint (also known as plain dovetail) joint, is where the end grain of both boards is visible when the joint is assembled. Through dovetails are common in carcass and box construction.

Traditionally, the dovetails would have often been covered by a veneer. However, dovetails have become a signature of craftsmanship and are generally considered a feature, so they are rarely concealed in contemporary work.

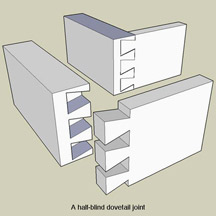

A half-blind dovetail joint is used when the craftsman does not wish end grain to be visible from the front of the item. The tails are housed in sockets in the ends of the board that is to be the front of the item so that their ends cannot be seen.

A half-blind dovetail joint is used when the craftsman does not wish end grain to be visible from the front of the item. The tails are housed in sockets in the ends of the board that is to be the front of the item so that their ends cannot be seen.

Half-blind dovetails are commonly used to fasten drawer fronts to drawer sides. This is an alternative to the practice of attaching false fronts to drawers constructed using through dovetails.

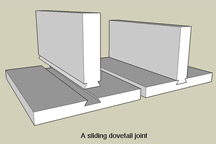

The sliding dovetail joint is a method of joining two boards at right angles, where the intersection occurs within the field of one of the boards, that is not at the end. This joint provides the interlocking strength of a dovetail.

The sliding dovetail joint is a method of joining two boards at right angles, where the intersection occurs within the field of one of the boards, that is not at the end. This joint provides the interlocking strength of a dovetail.

Sliding dovetails are assembled by sliding the tail into the socket. It is common to slightly taper the socket, making it slightly tighter towards the rear of the joint, so that the two components can be slid together easily but the joint becomes tighter as the finished position is reached.

Butt Joint Info

Butt Joint is a joinery technique in which two members are joined by simply butting them together. The butt joint is the simplest joint to make since it merely involves cutting the members to the appropriate length and butting them together. It is also the weakest because unless some form of reinforcement is used (see below) it relies upon glue alone to hold it together. Because the orientation of the members usually present only end grain to long grain gluing surface, the resulting joint is inherently weak.

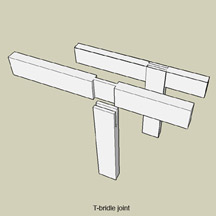

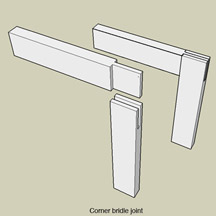

Bridle Joint Info

Bridle Joint is a woodworking joint, similar to a mortise and tenon, in that a tenon is cut on the end of one member and a mortise is cut into the other to accept it. The distinguishing feature is that the tenon and the mortise are cut to the full width of the tenon member.

The corner bridle joint (also known as a slot mortise and tenon) joins two members at their respective ends, forming a corner. This form of the joint is commonly used to house a rail in uprights, such as legs. It provides good strength in compression and is fairly resistant to racking, although a mechanical fastener or pin is often required. The bridle joint is very popular in workbench construction.

Butterfly Joint Info

Butterfly Joint is a type of joint used either to hold two or more wooden boards together, or to keep two halves of a board that have already started to split from splitting further. They may also be used to stabilize the core of a knothole, preventing it from dropping out over time.

A butterfly joint resembles two dovetails connected at the narrow part. A negative of the hole is cut out of the board the butterfly will be placed in and the butterfly is then fitted, keeping the joint together. The wood used for the butterfly is usually a contrasting wood, often walnut.

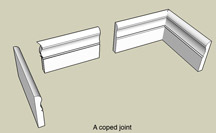

Coping/Scribing Joint Info

Coping Or Scribing Joint, coping or scribing is the woodworking technique of shaping the end of a moulding or frame component to fit the contours of an abutting member. Most English speaking countries outside the US use the terms scribe and scribing. Coping is commonly used in the fitting of skirting and other moldings in a room. It allows for clean joints between intersecting members when walls are not square to each other. The other method of fitting these moldings that is commonly used is the mitre joint but this technique relies upon the walls being at 90° to each other for neat results.

Coping is only ever used for internal corners. External corners are always mitered. The main reason that scribed joints are used is that timber shrinks in width far more than it does in length. By using a scribed joint rather than an internal mitre joint, the effect of shrinkage is minimized. Also, it is possible to arrange the scribed joints pointing away from the most common viewpoint (usually the doorway of a room) and so present the best appearance.

A scribed joint (right end of sketch) is derived from an internal miter cut (left end) by cutting along the inside face of the mitre cut at a right angle to the board, typically with a coping saw.

Coping is also commonly used in cabinet making for moldings and frame components. The rails in frame and panel construction are commonly cope cut to fit the profile of the stiles. The technique is also common in the construction of doors and windows.

Rail and Stile Info

Rail and Stile - Frame and panel construction (also called "rail and stile") is a woodworking technique often used in the making of doors, wainscoting, and other decorative features for cabinets, furniture, and homes. The basic idea is to capture a 'floating' panel within a sturdy frame, as opposed to techniques like slab drawer fronts which are simply single pieces of material with exposed end-grains. Usually, the panel is not glued to the frame - it is left to 'float' within it so that seasonal movement of the wood comprising the panel does not distort the frame.

Frame and panel construction at its most basic consists of five members: The panel and the four members which make up the frame. The vertical members of the frame are called stiles while the horizontal members are known as rails. A basic frame and panel item consists of a top rail, a bottom rail, two stiles, and a panel. This is a common method of constructing cabinet doors and these are often referred to as a five piece door. In larger panels it is common to divide the panel into one or more sections. To house the extra panels, dividing pieces known as mid rails and mid stiles or muntins are added to the frame.

More Joinery Info

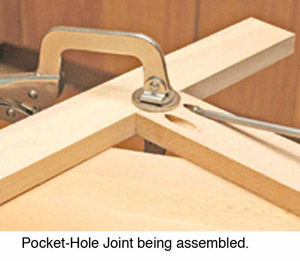

Pocket-Hole Joinery, Pocket-Screw Joinery, or Kreg Joinery involves drilling a hole at an angle into one work-piece, and then joining it to a second work-piece with a self-tapping screw. The technique, in addition to doweling, has its roots in ancient Egypt. Egyptians clamped two work-pieces together and bored a hole at an angle from the outside work-piece into the second work-piece. They then inserted a dowel with glue, and cut it off flush with the outermost surface.

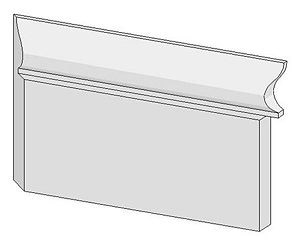

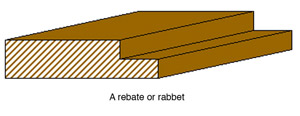

A rabbet (also known as rebate) is a recess or groove cut into the edge of a piece of machinable material, usually wood. When viewed in cross-section, a rabbet is two-sided and open to the edge or end of the surface into which it is cut. The spelling rabbet is probably a derivation of rebate, the latter being more common outside of North America. An example of the use of a rabbet is in a glazing bar where it makes a provision for the insertion of the pane of glass and putty. It may also accommodate the edge of the back panel of a cabinet. It is also used in door and casement window jambs.

Tongue and groove joint - A strong joint, the tongue and groove joint is widely used for re-entrant angles. The effect of wood shrinkage is concealed when the joint is beaded or otherwise moulded. In expensive cabinet work, glued dovetail and multiple tongue and groove are used. Tongue and groove or T&G is a method of fitting similar objects together, edge to edge, used mainly with wood: flooring, parquetry, panelling, and similar constructions. Tongue and groove joints allow two flat pieces to be joined strongly together to make a single flat surface. Before plywood became common, tongue and groove boards were also used for sheathing buildings and to construct concrete form work.

Each piece has a slot (the groove) cut all along one edge, and a thin, deep ridge (the tongue) on the opposite edge. The tongue projects a little less than the groove is deep. Two or more pieces thus fit together closely. The joint is not normally glued, as shrinkage would then pull the tongue off. For many uses, tongue and groove boards have been rendered obsolete by the introduction of plywood and later composite wood boards, but the method is still used in good-quality flooring.Plywood may also be tongued all round to fit it flush into a framed structure, and plywood for sub-floors used in platform framing is often supplied with tongue and groove edges. When joining thicker materials, several tongue and groove joints may be used one above the other.

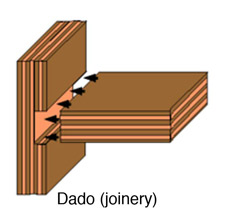

Dado/Housing/Trench Cutting Info

A dado (US and Canada), housing (UK) or trench (Europe) is a slot or trench cut into the surface of a piece of machinable material, usually wood. When viewed in cross-section, a dado has three sides. A dado is cut across, or perpendicular to, the grain and is thus differentiated from a groove which is cut with, or parallel to, the grain. A dado may be through, meaning that it passes all the way through the surface and its ends are open, or stopped, meaning that one or both of the ends finish before the dado meets the edge of the surface.

Dougong Info

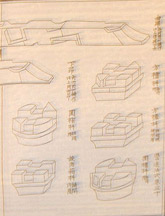

Dougong (in Chinese literally "cap [and] block") is a unique structural element of interlocking wooden brackets, one of the most important elements in traditional Chinese, Japanese, Korean, Malaysian and Singaporean architecture. The use of dougong first appeared in buildings of the late centuries BC and evolved into a structural network that joined pillars and columns to the frame of the roof.

Diagram of bracket and cantilever arms from the building manual Yingzao Fashi (published in 1103) of the Song Dynasty.

History of Dougong - Dougong was widely used in the ancient Chinese during the Spring and Autumn Period (770-476 BC) and developed into a complex set of interlocking parts by its peak in the Tang and Song periods. The pieces are fit together by joinery alone without glue or fasteners, due to the precision and quality of the carpentry.

After the Song Dynasty, brackets and bracket sets became more ornamental than structural when used in palatial structures and important religious buildings, no longer the traditional dougong. In traditional Chinese architecture, wood components such as beams, brackets, roof frames and struts were made to interlock with perfect fit, without using fasteners or glues, enabling the wood to expand and contract according to humidity. Archaeological evidence from Chinese sites show that by the end of the Neolithic period, mortise and tenon joinery was employed in Chinese construction.

Dougong inside the East Hall timber hall of Foguang Temple, built in 857 during the Tang Dynasty

The Facts Speak for Themselves - ArtFactory.com is the Right Choice

When you purchase investment quality wood furnishings, doors, gates, cabinets, lighting and hardware they will appreciate and keep up with inflation or exceed most other investments. For this reason, becoming wealthy has very little to do with a higher education or having a lot of extra money.

It is truly making wise decisions and a state of mind that allows for you to pay once for a good value and continue to grow wealth while enjoying living in your investment. Not to mention this type of investing has many other benefits, such as priceless family heirlooms that have meaning and the ability to pass on your legacy to future generations.

We Offer Our Facility to Advance Go Green Technology and Advancement of the Arts to Contributors

We offer use of our facility and the sharing of the experience of our master craftsmen in return for these contributions when available, thus allowing for hands on experience training in the lost arts. We also allow use of our facility for project development in related fields under any accredited school program. Products produced in these programs are sold and proceeds are used to fund the advancement of these programs with no weight to profit.

We also offer the use of our facility for the advancement of environmental energy saving designs in connection with government funded Go Green development. These energy saving designs must be associated with our natural material, building projects such as doors/windows etc. without affecting the artistic value. This is a not-for-profit program provided by ArtFactory.com in hopes of advancing new technology in conjunction with arts and crafts as it relates to our contribution to the world of fine art craftsmanship. Call us today at 1-800-292-0008.

Source: https://wikipedia.org

Scarf Joint in Woodworking

Scarf Joint in Woodworking