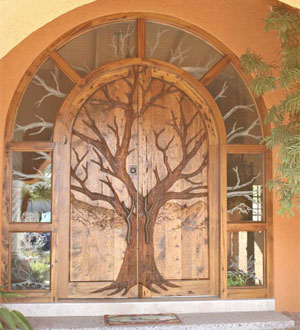

Fine Art Wood & Iron Finishes

All finishes on our custom fine art doors, gates, furniture, and furnishings are processed and hand applied by our master finishers and to world class fine art antiquity standards. Learn more about ArtFactory.com's high quality finishes and techniques on wood and iron furnishings below.

We Are One Of The World's Authorities on Finishes for Fine Art Wood Furniture and Iron Hardware

We are an authority on fine art, solid wood furniture and wrought iron hardware finishes. Over the years we have developed and redeveloped many of the finish processes that have become the accepted standard finishes for fine art furniture manufacturers and artisans around the world. We have pioneered new finishes and processes (some trade secrets) with the focus, for several decades, on developing water base lacquers due to the environmental requirements of our planet, as well as the health and safety of our consumers and employees. Today we continue to improve on old tried and tested finishes as well as continuing our effort to go green.

When we repair and refinish a museum quality antique furnishing for a museum or insurance claim, flood, fire, etc., we must use the exact finishes and methods as were originally used. This means we cannot use our environmentally friendly, modern, water base processes. However, we do take every safety precaution, and have the state of the art, down draft, environmentally controlled booths and equipment to keep these processes safe for our personnel and consumers.

So, the caveat for using water base finish products, is due to our fine art, original craft furniture and restoration services - commissioned by museums, insurance companies, and antique collectors - which force us to use the old standard methods of finishing. When we hand build a historical, fine art, original craft item, we build it in the same hand and materials - and processes - as it was built by the original producer in the era it was originally produced in. For example, if we are working on a Thomas Chippendale, Richard Wood, Robert Adam, or Gustav Stickley, etc. piece, it will be finished using the exact methods and materials - taking care as to not disturb the natural patinas - as the original. This is the only way we can restore or rebuild antiques, so each piece will maintain - as close as possible - its value, integrity, and historic quality. Notice: No repaired antique or original craft piece will ever be restored to it antique or original full value due to disclosure of damage repaired required on these items.

Table of Contents

- * H. J. Nick - Artist Designer

- - Investment Quality Is Important

- - Guarantee & Satisfaction Warranty

- - How it's Made

- - Fine Furnishings Begin with Natural Materials

- - How It's Made - Wood Products

- - Master Hand Carving Information

- - How Its Made "Iron" - Master Blacksmithing

- - Facts About Leather Furniture

- - Stone, Marble & Granite

- - Art Factory Fine Art Finish Procedures

- - Finishes To World Class Antiquity Standards

- - American Vintage Restoration

- - More Door Details / Installation Info

- - Original Art or Limited Edition

- - Become an Interior Designer

- - A True Story About Mary

- - Dealer Design Policies & Rules

- - Web Site Terms And Conditions

- - Policies and Terms - A Must Read

Wood Finishes and Techniques on Our Custom Furnishings

Wood Finishes and Techniques on Our Custom Furnishings

All of our wood products are cured with evaporative, reactive, coalescing finishes. These include environmentally friendly, water base lacquers and stains that are fumed or hand rubbed into the wood creating world class fine art perfection. We never use faux finishes, veneers, laminates, or paste boards in our custom wood doors, gates, furniture, or furnishings. All of our creations are built "The Old Fashioned Way True To Our Heritage" - by the hands of our world class Master Craftsmen - to ensure that your custom wood product is a true investment quality, fine art furnishing.

We believe in educating our customers, and through education and the understanding of how finishes are processed - in relation to your furniture, door, or lighting choice - you will fully appreciate the true value of each piece. When a finish is applied correctly, it takes time and master-craftsmanship to produce the fine art investment quality furniture. Remember that no fast, corner cutting, automated methods can produce the same high quality finish as the handcrafted fine art finishes applied to our custom gates, doors, and furnishings at Scottsdale Art Factory.

There 3-Types of Finish Processes - Evaporative - Reactive - Coalescing, which include environmentally friendly water base lacquers and stains.

Evaporative finishes

Evaporative finishes use alcohol, acetone, and nitro-cellulose lacquer thinners as solvents and thinners. Nitro-cellulose lacquers and shellac are in this group. The solids are soft and string-like in solution but as the solvents evaporate they lock together in a solid mass like dried pasta. Successive layers burn into one another and form a contiguous whole. Solvent will re-soften the film, e.g., lacquer thinners will soften cured lacquer, and alcohol softens cured shellac.

Cellulose polishes and thinners, and lacquer and lacquer thinners, are the in the same family of finishes. Lacquer thinners, a.k.a. cellulose thinners, do come in different flavors, e.g., 'hot' or 'fast' thinners, and 'cool' or 'slow' thinners, depending on how the formulation is meant to perform.

Wax is an evaporative finish because it is dissolved in turpentine, or petroleum distillates, to make the familiar soft paste. After these distillates evaporate all that's left is the wax.

Reactive finishes

Reactive finishes use solvents such as white spirits and naphtha. Oil varnishes and linseed oil are reactive finishes which change chemically when they cure, unlike evaporative finishes. At cure, the solvent/thinner evaporates and the resins cluster tighter together, and then a chemical reaction occurs causing the resins to cross link in a different chemical format - like loose scaffolding that suddenly bolts together.

Scuff sanding is necessary between layers of cured finish so that subsequent applied layers have something to grip on to effectively. The solvent won't re-dissolve the cured film, e.g., white spirits does not soften cured oil based varnish.

Note: Pre-catalysed and post catalysed "lacquers" (a.k.a. acid catalysed lacquers) are reactive finishes. The term lacquer is, in this sense, used inconsistently from product to product.

Oil based varnishes dry from the top down by reacting with oxygen. The catalysed lacquers dry from the bottom up (which is like the evaporative finishes), and the solvents migrate upwards to the film surface and then out leaving behind molecules that then cross-link.

Tung oil and linseed oil are reactive finishes that cure by reacting with oxygen, but do not really form film finishes when cured.

Coalescing finishes

Coalescing finishes, water based finishes fall into the coalescing category. Water based lacquers are transparent, UV stable, and durable after approximately a 10-day curing period. They are safer than oil-based, with fewer volatile organic compounds (VOCs), can be brushed or sprayed on, and are fast drying, demanding care in application techniques. If necessary, they can be stripped using paint removers. Bad coats do not meld, leading to white rings if rubbing out cuts through the coat; this finishing is for professionals only.

Coalescing finishes, water based finishes fall into the coalescing category. Water based lacquers are transparent, UV stable, and durable after approximately a 10-day curing period. They are safer than oil-based, with fewer volatile organic compounds (VOCs), can be brushed or sprayed on, and are fast drying, demanding care in application techniques. If necessary, they can be stripped using paint removers. Bad coats do not meld, leading to white rings if rubbing out cuts through the coat; this finishing is for professionals only.

Clear finishes are intended to make wood look good and meet the demands to be placed on the finish. Choosing a clear finish for wood involves trade-offs between appearance, protection, durability, safety, requirements for cleaning, and ease of application.

Shellac should be considered in two different ways. It is used as a finish, and as a way to manipulate the wood's ability to absorb other finishes by thinning it with denatured alcohol. The alcohol evaporates almost immediately to yield a finish that is completely safe but shellac will attach itself to virtually any surface, even glass, and virtually any other finish can be used over it.

Notice To Our Dealers: As experts, we always educate and advise our customers of the best finish methods and process to be used on each product. We also understand that "the customer is always right". However, if you do not accept our recommendations on the proper finishes, per your application, it may void any normal structural warranties on products per our discretion.

Beware of Automated Wood Finishing Methods

Automated Finish Methods = Faster Production Time = Low Quality = Higher Profits = Future Yard Sale Items

Automated Wood Finishing Methods

Manufacturers who mass produce name brand throw-away products and furnishings, implement automated flatline finish systems. A flatline finishing system is a long series of processing stations that may include sanding, dust removal, staining, sealer and topcoat applications. As the name suggests, the primary part shapes are flat. Liquid wood finishes are applied via automated spray guns in an enclosed environment or spray cabin. The material then can enter an oven, or be sanded again, depending on the manufacturer's setup. The material can also be re-entered into the assembly line to apply another coat of finish, or continue in a system that adds successive coats depending on the layout of the production line. Two very common methods of automating the wood finishing process are the hang-line approach and the towline approach.

In the hang-line approach, wood items being finished are hung by carriers or hangers that are attached to a conveyor system that moves the items overhead or above the floor space. The conveyor itself can be ceiling mounted, wall mounted or supported by floor mounts. A simple overhead conveyor system can be designed to move wood products through several wood finishing processes in a continuous loop. The hang-line approach to automated wood finishing also allows the option of moving items up to warmer air at the ceiling level to speed up the drying process.

The towline approach to automating wood finishing uses mobile carts that are propelled by conveyors mounted in or on the floor. This approach is useful for moving large, awkward shaped wood products that are difficult or impossible to lift or hang overhead, such as four-legged wood furniture. The mobile carts used in the towline approach can be designed with top platens that rotate either manually or automatically. The rotating top platens allow the operator to have easy access to all sides of the wood item throughout the various wood finishing processes such as sanding, painting and sealing.

ArtFactory.com does NOT use Automated Methods of Finish

There is nothing wrong with automated finished furniture, if you're just trying to fill the space with throw away furniture. You should keep in mind, using these methods usually means using fake materials, and inferior sub-straights. No matter the brand name, this type of furniture will never increase in value, or become a cherished family heirloom or valuable antiquity. All of our custom handcrafted fine art furnishings include hand rubbed finishes to world class antiquity standards.

Never Confuse Faux Finishing With True Antique Refinishing

Never Confuse Faux Finishing With True Antique Refinishing

There are a great variety of both traditional and modern finishes, including the use of faux finishes. One modern development by production manufacturers in refinishing is the so called art of distressing or antiquing, making the finishes of pieces look older. This method is never used on true investment quality furniture or antiques.

While refinishing is often undertaken to salvage an old piece of furniture, in the case of antique furniture refinishing, it has been known to significantly reduce the overall value of the piece. However, refinishing (or re-polishing) a more modern piece of furniture, to return it to almost showroom condition, will sometimes temporally enhance the value. Note: Touch up or patch up - no matter how masterfully it is performed - is never a proper method of restoring antiques or high quality furniture. This always results in reducing the value of a piece.

ArtFactory.com never uses faux finishing. In the case of antique furniture, refinishing has been known to significantly reduce the overall value of a high value piece.

Wood Finish Department at ArtFactory.com

ArtFactory.com features a state-of-the-art finishing department that offers hundreds of finish options. A large percent of our custom wood furniture orders are finished in ten or more - process, hand rubbed, fumed in, clear lacquers and many other finish products. The reason is simple: all professionals agree, natural wood furniture never goes out of style.

Natural Hard & Exotic Woods and Over 400 Custom Stain Colors to Choose From or Custom Match

Designers/customers may also choose from over four hundred designer stain colors from the Behr paint color chart or custom samples we provide. Customers may select items with a matte, satin, semi-gloss, wax, french polish or many exterior or interior finishes, or conversely order barn wood appearances, raised grain, weathered, old Spanish, or saw tooth textured finishes. All our exclusive finishes are environmentally safe, non-toxic, and are applied by hand then rubbed to perfection the "Old Fashioned Way". Additionally, customers have the option to custom match a color to a sample from any source or material, usually with in the original budget or a reasonable up charge if process chosen is at additional labor and material expense. We will send you finish samples for final approval prior to the completion of an order. Multi color finishes, french polish etc. and some other processes that are available require additional steps, and are offered at an additional charge.

All backs, fronts, inside and outside of all our custom furniture and furnishings are made from solid wood, and are fully finished. All backs and interiors are fully finished - hand rubbed to match all exteriors. This allows any piece to be displayed in the middle of a room, as well as against a wall. This makes all of our custom designed and handcrafted furnishings ideally designer friendly.

Learn more about our - Hand Rubbed Wood Finish Procedure

Wrought Iron and Other Metal Patina Finishes

Patina is a film on the surface of bronze or similar metals (produced by oxidation over a long period or by a natural chemical process); a sheen on wooden furniture produced by age, wear, and polishing; or any such acquired change of a surface through age and exposure. On metal, patina is a coating of various chemical compounds such as oxides or carbonates formed on the surface during exposure to the elements (weathering). Patina also refers to accumulated changes in surface texture and color that result from normal use of an object, such as a coin or a piece of furniture, over time.

Patinas are restricted to exposed surfaces and are fragile (that is, they can flake off).

One reason bronze is so highly valued in statuary is that its patina protects, or passivates, it against further corrosion. This natural patina is solid and seldom shows a tendency to flake. Brass is also resistant to corrosion, but it is, in the long run, not as attractive since local pitting shows against the shiny background.

The etymology of the word "patina" comes from the Latin for "shallow dish". Figuratively, patina can refer to any fading, darkening or other signs of age, which are felt to be natural or unavoidable (or both). The natural chemical process by which a patina forms is called patination, and a work of art coated by a patina is said to be patinated.

Acquired Patina

The green patina that forms naturally on copper and bronze, sometimes called verdigris, usually consists of a mixture of chlorides, sulphides and carbonates, copper carbonate or copper chloride. Atacamite is another name for the patina compounds. Verdigris is usually more specifically the artificial form and can be produced on copper by the addition of vinegar (acetic acid). Such a verdigris is water-soluble and will not last on the outside of a building like a "true" patina. It is instead usually used as pigment. One example of a patina is a green surface texture created by slow chemical alteration of copper, producing a basic carbonate. It can form on pure copper objects as well as alloys which contain copper, such as bronze or brass. Often, antique and well used firearms will develop a patina on the steel after the bluing, parkerization, or other finish has worn. Firearms in this state are generally considered more valuable than ones that have been re-blued or parkerized. The patina protects the firearm from more damaging rust that would occur were the patina to be polished off

Applied Patina

Applied Patina

Artists and metalworkers often deliberately add patinas as a part of the original design and decoration of art and furniture, or to simulate antiquity in newly-made objects. A wide range of chemicals, both household and commercial, can give a variety of patinas. They are often used by artists as surface embellishments either for color, texture, or both. Patination composition varies with the reacted elements and these will determine the color of the patina. For copper alloys, such as bronze, exposure to chlorides leads to green, while sulfur compounds (such as "liver of sulfur") tend to brown. The basic palette for patinas on copper alloys includes chemicals like ammonium sulfide (blue-black), liver of sulfur (brown-black), cupric nitrate (blue-green) and ferric nitrate (yellow-brown).

For artworks, patination is often deliberately accelerated by applying chemicals with heat. Colors range from matte sandstone yellow to deep blues, greens, whites, reds and various blacks. Some patina colors are achieved by the mixing of colors from the reaction with the metal surface with pigments added to the chemicals. Sometimes the surface is enhanced by waxing, oiling, or other types of lacquers or clear-coats. More simply, the French sculptor Auguste Rodin used to instruct assistants at his studio to urinate over bronzes stored in the outside yard.

Patina is also found on slip rings and commutators. This type of patina is formed by corrosion, what elements the air might hold, and residue from the wear of the carbon brush and moisture; thus, the patina needs special conditions to work as intended. Patinas can also be found in woks or other metal baking dishes, which form when properly seasoned. The patina on a wok is a dark coating of oils that have been burned onto it to prevent food sticking and to enhance the flavor of the foods cooked in it. Steaming foods or using soap on a wok or other dishware could damage the patina and possibly allow rust.

The Statue of Liberty gets its green color from the natural patina formed on its copper surface. A patina layer takes many years to develop under natural weathering. A copper roof will patinate faster than a copper facade, due to the longer dwell time of water on the surface. Buildings in coastal / marine locations will weather and develop a patina layer faster than ones in inland areas. For example, a new copper facade in central London will most likely not develop a "typical" green patina until after 50 years. Facade cladding (copper cladding) with alloys of copper, e.g. Brass or Bronze, will weather differently to "pure" copper cladding. Even a lasting gold color is possible with copper-alloy cladding. Look at Colston Hall in Bristol, or the Novotel at Paddington Central, London. There you can see some colours that one might not have expected from copper / copper-alloy cladding.

Value of Patina

Apart from the aesthetic appearance and practical protection of patination, antique experts confirm that an object's value increases when its patination is intact because it is an important effect of the aging process and this evidential history is reflected in the value of the piece. In terms of antiques then, patina is everything that happens to an object over the course of time. The nick in the leg of a table, a scratch on a table top, the loss of moisture in the paint, the crackling of a finish or a glaze in ceramics, the gentle wear patterns on the edge of a plate. All these things add up to create a softer look, subtle color changes, a character. Patina is built from all the effects, natural and man-made, that create a true antique.

Repatination

Repatination

In the case of antiques, several views are held on the value of patination and its replacement if damaged, known as repatination. Preserving a piece's look and character is important, and removal or reduction may dramatically reduce its value. If patination has flaked off, repatination may be recommended. Appraiser, Reyne Haines notes that "a repatinated metal piece will be worth more than one with major imperfections in the patina," but less than a piece still with its original finish.

Our Exclusive Formulated Patina Finishes - Natural Iron Oxides Hand Applied at 1000 Degrees

Our beautiful patina finishes are hand applied, using a special patented and master crafted process where natural oxides are bonded into the metal at over 1000 degrees.

This permanent patina finish beautifies with age and will stand the test of time. ArtFactory.com does not paint, or faux finish, any of our master blacksmith iron creations. Paint fades, chips and cracks over time, powder coating flakes off and natural patinas last forever.

No Drop Forged Casted Copies & No Paint or Powder Coated Finishes

Learn more about our custom doors, gates, furniture, lighting, and furnishings from ArtFactory.com:

- How It's Made

- Wood Furniture and Furnishings

- Master Blacksmith Iron Works

- Natural Products

- Hand Rubbed Wood Finish Procedures

- More Custom Product Information

For more information about our products, please contact us at 1-800-292-0008.

Never Confuse Faux Finishing With True Antique Refinishing

Never Confuse Faux Finishing With True Antique Refinishing Applied Patina

Applied Patina Repatination

Repatination